|

Industrial Waste Water Treatment

Page 3 / 4 |

|

|

|

|

|

| |

|

|

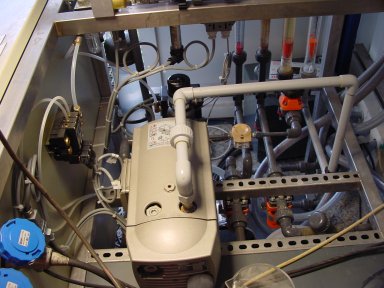

Waste water treatment

in a factory for the treatment of industrial wastes - pilot plant with porous

membranes (B.R.M.). |

| |

|

| |

Reactor of clarification by porous membranes

immersed in a biological reactor. |

| |

|

| |

Aims realised : |

| |

Removal of C-load |

| |

Guarantee the nitrification with an "hard" load. |

| |

Guarantee the separation between the activated

sludge and the treated water by immersed porous membranes. |

| |

|

| |

|

|

|

|

| |

|

|

Sand filtration for service water production |

| |

|

| |

Water comes from a clarification tank after biological

reactors. |

| |

The treated water is used for secondary utilities in

the factory. |

| |

|

| |

Production rate : 3 m³/h |

| |

Automatic washing up |

|

|

|

| |

|

|

Water treatment in a

metallurgy factory

before rejection in surface water |

| |

|

| |

Flow rate : 500 m³/h |

| |

|

| |

Coagulation |

| |

Settling - clarification tank with scraper |

| |

|

|

|

|

| |

|

|

Water treatment,

in a factory for the treatment of

industrial wastes, before rejection in surface water |

| |

|

| |

End treatment by flocculation, settling by

lame on HYDROPAC-CL |

| |

|

| |

Flow rate : 50 m³/h |

| |

|

| |

|

| |

|

| |

|

|

|

|

| |

|

|

|

Industrial waste water

treatment in a glass industry. |

| |

|

|

| * |

Reactor R.A.P.T. - for

coagulation |

|

| * |

Reactor R.A.P.D. - for

flocculation |

|

| * |

Clarification by flotation on

HYDROFLOT |

|

| |

|

|

| |

Flow of rejection in

surface water : 35 m³/h |

|

| |

|

|

|

|

|

| |

|

|

Final treatment after output of physico-chemical

treatmentplant |

| |

|

| |

Sand filtration |

| |

|

| |

Flow of rejection in

surface water : 100 m³/h |

| |

|

| |

|

| |

|

|